1330A 9kW CNC Nesting Router For Wood Processing Applications

Meet the 1330A - a clever wood cutting machine that brings

professional results to your workshop. It handles everything from

sturdy cabinet boxes to fancy decorative doors. With its smart

design and reliable performance, this machine makes complicated

jobs simple.

What Makes It Special:

This machine thinks ahead. Its Taiwan-made brain (the control

system) is straightforward to use. The powerful 9kW spinning head

can switch between 12 different tools automatically. Imagine

finishing a detailed carving and having the machine immediately

change to a drilling tool without any pause. That's the efficiency

it brings.

Precision is key. The machine glides on solid steel tracks, while

its driving mechanism uses quality gears for perfect movement. Your

cuts will be sharp and accurate every time. The table has a smart

vacuum system that holds your material securely in place, plus two

rolling presses that keep the board flat during operation -

especially useful for thin materials.

It keeps your workspace tidy. A specially designed cover captures

most of the dust right at the source, working seamlessly with your

dust collection system. All cables move safely within protective

chains, preventing wear and tear.

Built to last, the machine's body is constructed from heavy-duty

steel that's been heat-treated for extra strength. This means it

stays steady and reliable even during demanding projects.

Technical Specifications

| Component | Specification |

|---|

| Machine size | 4300*2000*2100mm |

| Sheet processing dimensions | 3050*1220*18mm |

| Running Speed | 60m/min |

| Drive type | X/Y rack; Z screw |

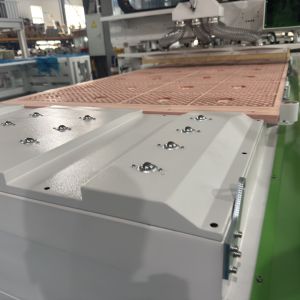

| Table structure | Partitioned vacuum adsorption table |

| Spindle power | 9kw |

| Spindle speed | 18000~24000r/min |

| Maximum operating speed | 20m/min |

| Operating voltage | AC380/3PH/50HZ |

Customization Available: We offer model and configuration

customization based on customer requirements. Orders require

prepayment. Please contact our team for specific pricing based on

your desired configuration.

Key Features

Control System: Taiwan LNC-Buyu control system. Stable, fast response,

user-friendly interface for simpler, more intuitive operation.

Zoned vacuum adsorption table with screw fixation. Patented design, stronger suction, prevents

small boards from shifting.

Spindle: CC / 9KW high-power automatic tool change spindle,

18000-24000r/min. High cutting torque, fast speed, smooth

operation.

Linear 12-tool magazine. Meets customer needs for processing both cabinets and doors.

Currently the highest tool capacity on the market.

XYZ drive motors: Servo motors 1.5KW. Drives: Servo drives (matched to the above

motors).

Patented dust collection hood. Excellent dust collection effect, even cleans dust from the

cutting groove.

Reducer: Japan Shimpo reducer, using helical planetary structure design for

higher precision and longer service life.

Steel beam. Both the bed and beam undergo quenching and shot blasting,

processed by a 5-face CNC machining center.

Guide Rails: Taiwan steel guide rails (25MM), higher precision, higher

hardness.

11KW vacuum pump. High-power adsorption ensures small boards do not shift.

High precision, 1.5 module P &C rack and pinion transmission. Fast speed, high accuracy, wear-resistant material.

Drag chain: Imported layered and separated type. Each wire is separated

individually for easy troubleshooting.

Enhanced Functionality

- Combines door panel and cabinet machining capabilities

- Rapid plunge function for efficient drilling operations

- Form sequencing processing function for streamlined workflow

- Start-from-behind function for convenient operation

Why Choose This Machine?

This machine combines two functions in one unit. You can create

basic cabinet components and elaborate door designs using the same

equipment. It includes time-saving features like rapid drilling,

the ability to queue multiple projects, and a convenient start

button at the loading position - no more running back and forth to

begin a new job.

Frequently Asked Questions

Q1: Can customized services be supported?

A1: Yes, we can customize the color, size and logo you need.

Q2: Where is your factory located?

A2: We are a Chinese manufacturer in Qingdao city, Shandong

province.

Q3: Can you make the machine according to my design or prototype?

A3: Yes. We have professional designers to create the most suitable

design and production plan for your requirements.

Q4: This is the first time I use this kind of machine, is it easy

to operate?

A4: We provide guide videos and English instruction manuals with

the machine. Our team offers free professional guidance until you

can operate the machine proficiently.

Q5: What's your MOQ and delivery?

A5: Minimum order quantity is 1 set. We ship directly to your

country's port - please provide your port name for the best

shipping rates and machine pricing.

Q6: How is your after sales service?

A6: Our sales team is available 24/7. We also provide overseas

installation services.

Q7: If my machine is broken, can you repair it for me?

A7: Yes. We offer free online training. For major issues during

warranty period, we provide repair services.