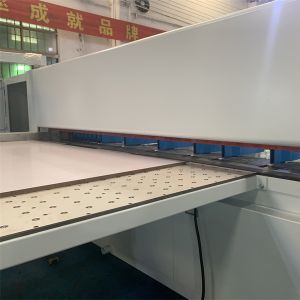

CNC Beam Saw 3300mm - Auto Cutting & Optimization Panel Saw

The CNC Beam Saw is a state-of-the-art automated cutting solution

designed for modern woodworking and panel processing industries.

Combining robust construction, high-precision servo systems, and

intelligent software integration, this machine delivers exceptional

performance, accuracy, and ease of use. Whether you are optimizing

raw material usage, managing complex cutting plans, or seeking to

reduce manual labor, the CNC Beam Saw is engineered to meet the

highest standards of productivity and reliability.

Fully Automated Operation

From loading to unloading, the CNC Beam Saw ensures a seamless and

fully automated workflow. Operators simply place the raw panel on

the worktable or loading device, activate the clamping system, and

initiate the automated process. The machine then performs:

- Automatic positioning

- Automatic edge alignment

- Automatic sawing

- Automatic material discharge

All operations are executed based on pre-input data, minimizing

human intervention and maximizing consistency.

Key Advantages

- Robust Main Structure

- The table is constructed from 18mm steel plates bent and welded

into square tubes, reinforced and annealed at zero critical

temperature to prevent deformation and ensure long-term sawing

accuracy.

- Advanced Electrical Control System

- Equipped with Taiwan Yonghong PLC and EASUN solenoid valves for

stable, durable, and reliable control.

- User-Friendly Interface

- The intuitive panel display offers easy operation, comprehensive

guidance, fault alarms, and troubleshooting. It supports sawing

plan editing, simulation, and compatibility with various

optimization and barcode management software.

- High-Performance Servo System

- Driven by INVT servo motors, the system responds quickly and

accurately to control commands, ensuring efficient and precise cuts

every time.

- Air Flotation Feed Table

- The ball-type air-floating table facilitates smooth and effortless

panel feeding, reducing friction and handling time.

- Powerful Saw Car Device

- Features a 16.5kW main and auxiliary motor system. The trolley uses

a magnetic sensor limit device, replacing older rod-type switches

prone to dust-related jams.

- Precision Clamping System

- High-performance pneumatic clamps with servo-driven positioning

ensure secure and accurate panel holding during operation.

- Linear Guide Rails

- Taiwan Yinchuang Technology steel belt square linear guides provide

low-noise, high-precision, and durable movement for long service

life.

- Automatic Lubrication System

- Ensures smooth operation by automatically lubricating guide rails

every 10 minutes after startup.

- Optimization Software (Optional)

- Enables remote monitoring, automatic layout optimization, barcode

printing, and surplus material management. Compatible with leading

design and optimization software.

- Side Leaning Device (Optional)

- Allows quick and accurate sawing of small panels with intelligent

side pushing functionality.

Technical Specifications

| Main and scoring saw power | 16.5kw |

| Maximum cutting length | 3200mm |

| Maximum cutting thickness | 85mm |

| Maximum sawing width | 3300mm |

| Minimum cross-cutting board size | 5mm |

| Minimum board size for vertical cutting | 40mm |

| Positioning method | Automatic |

| Servo positioning accuracy | 0.02mm |

| Sawing accuracy | ±0.2mm |

| Main saw blade outer diameter | 360mm |

| Main saw blade inner diameter | 30mm |

| Main saw speed | 4800r/min |

| Saw car servo motor | 2KW |

| Robot servo motor | 2kw |

| Cutting speed | 0-100 m/min, |

| Return speed | 120 m/min |

| High pressure blower | 4KW |

| Air pressure | 0.6-0.8MPA |

| Air flotation table specifications | 1750*540mm |

| Machine tool dimensions | 5030x5800x1900m |

| Power | 24.5KW |

Advanced Features

- Circular guide rails prevent slot jamming and dust adhesion

- Pneumatic floating ball table for effortless material handling

- Automatic sawing stroke positioning reduces idle time

- User-friendly control interface with troubleshooting guidance

- ERP-compatible software integration

- Rubber-coated pressing blocks for durability

- ±0.1mm positioning accuracy with servo-controlled robotic arm

- Opposed saw blade configuration for flawless cut quality

Frequently Asked Questions

Q1: Can customized services be supported?

A1: Yes, we can customize the color, size and logo you need.

Q2: Where is your factory located?

A2: We are a Chinese manufacturer in Qingdao city, Shandong

province.

Q3: Can you make the machine according to my design?

A3: Yes. Our professional designers will create the optimal

production plan for your requirements.

Q4: Is the machine easy to operate for beginners?

A4: We provide instructional videos and manuals, plus free

professional guidance until proficiency.

Q5: What's your MOQ and delivery terms?

A5: Minimum order is 1 set, shipped directly to your designated

port.

Q6: How is your after-sales service?

A6: 24/7 support with optional overseas installation services.

Q7: What about repairs during warranty?

A7: Free online training and repair services for warranty issues.

Contact us immediately for more product information! Special reminder: Custom configurations available. Orders require prepayment -

please confirm pricing with our staff based on your specific

requirements.