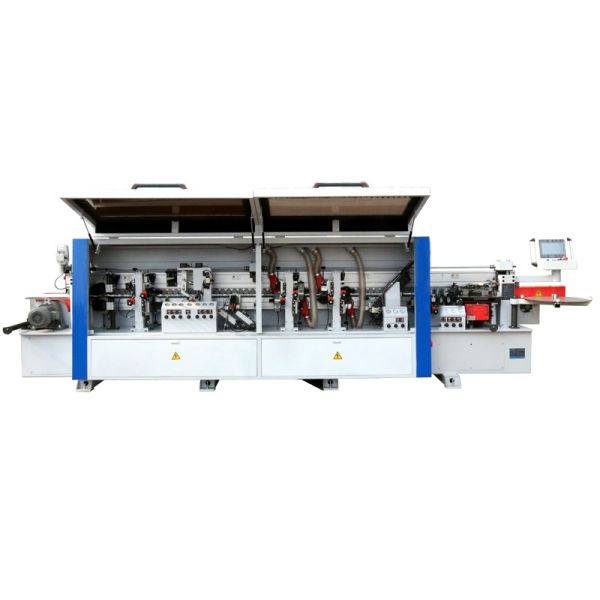

High Speed Full Automatic Corner Rounding CNC Edge Banding Machine

Specification

Overall dimensions | 7900*910*1540mm |

Min Panel Side | 300(L)*60(W) 150(L)*150(W) |

Feed speed | 15-23m/min |

Edge thickness | 0.2-3mm |

Panel Thickness | 10-60mm |

Panel Length | ≥150mm |

Panel Width | ≥60mm |

Working Air Pressure | 0.6Mpa |

Weight | 2950kg |

Total Power | 24.1kw |

Features

Double Trimming + Profiling System – Combines rough and fine

trimming with advanced profiling (tracking trimming) to achieve

complex edge contours and perfect smoothness.

Italian-Style Tracking Technology – The profiling unit adopts

imported or Italian-inspired copying technology, capable of

performing multiple contour effects that follow the workpiece shape

precisely.

Four-Mode Copying Function – Allows operators to switch between

different copying profiles for round, straight, beveled, or

R-shaped edges, ensuring versatility in design.

Precision Control System – Fine-tuned adjustment for trimming

depth, tracking sensitivity, and tool position provides maximum

processing accuracy.

High-Speed Stable Operation – The integrated system ensures

seamless transition between trimming and profiling, minimizing tool

marks and improving efficiency.

Advantages

1.Adopt domestic famous motor and high quality electrical

components.

2.The fuselage is firm and steady,thus increasing the stability of

the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its

precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double

finishing side within one workflow .The end cutting can be done at

the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used

for positioned location assured the panel materials processing

accuracy in a very high level.

8.Secondary Dust Exhaust System, mainly used for sawdust collection

during processing period, to keep the material smooth and clean.

9.The machine adopts the devices of sound insulation, controlling

of dust, platform frame Micro adjustment by manual operation.

Application

The machine is suitable for such plates: MDF, block board, solid

wood board, particleboard, polymer door plates, plywood etc,

straight line edging and trimming. Function:

pre-milling,gluing,edge cutting,end trimming, rough trimming, fine

rimming, corner trimming, scraping, buffing, slotting and so on.

Edging smoothly and edging line is straight. The machine is stable,

reliable and durable, with favorable price. It is especially

suitable for large and medium-sized furniture manufacturers.

Shipping

Shipping Information

The edge banding machine will be carefully packaged and shipped

within 15-30 days of order confirmation. Delivery times may vary depending on your

location and shipping method. Tracking details will be provided

once the shipment is dispatched, and we ensure secure packaging to

prevent damage during transit.

Delivery Timeline

We typically dispatch edge banding machines within 2-4 weeks after order confirmation. Depending on your shipping address,

delivery may take additional time, and we will provide tracking

information to monitor your order. All machines are securely packed

for safe delivery.

Shipping Terms

Upon receiving the order, the edge banding machine will be shipped

within 20-40 days. The exact delivery time will depend on the destination and

shipping method selected. We will send you tracking details once

your order has been shipped, and we ensure the equipment is safely

packaged to avoid transit damage.

Dispatch and Delivery

The edge banding machine will be processed and dispatched within 15-30 days of order receipt. Delivery time may vary depending on your

location, but rest assured that we will provide tracking

information once the item ships. Our team ensures the machine is

packed securely to prevent any damage during shipping.